Your laser project in “Lightspeed”

Lightspeed – cause sometimes fast isn’t fast enough! *

Have you got an urgent project? Then use our Lightspeed service. We have a warehouse containing a wide variety of materials and can flexibly adapt our machine capacities to meet your needs.

Get in touch and let us know your project specifications and deadline. We will do everything we can to get your components to you as quickly as possible.

*This service includes preferential treatment for your order in our production department. (For a fee, only possible if we have availability)

Our core competencies

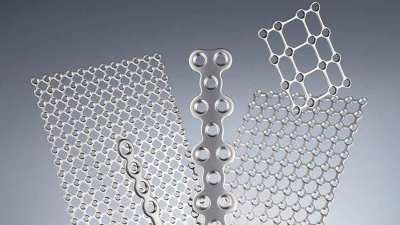

Medical technology

Reference : TRUMPF Group

For human and veterinary medicine, we can produce various implants and surgical components for you. Perfect implants are essential for a successful operation. Our wealth of experience in machining titanium and surgical stainless steel is the perfect starting point for an optimum result.

But it’s not just implants we do. We can also manufacture a large number of high-precision medical instruments that fulfil your requirements.

On request, we can undertake the following mechanical further processing stages on laser-cut components:

- grinding, mechanical/manual

- drilling

- countersinking

- isolating

- cleaning

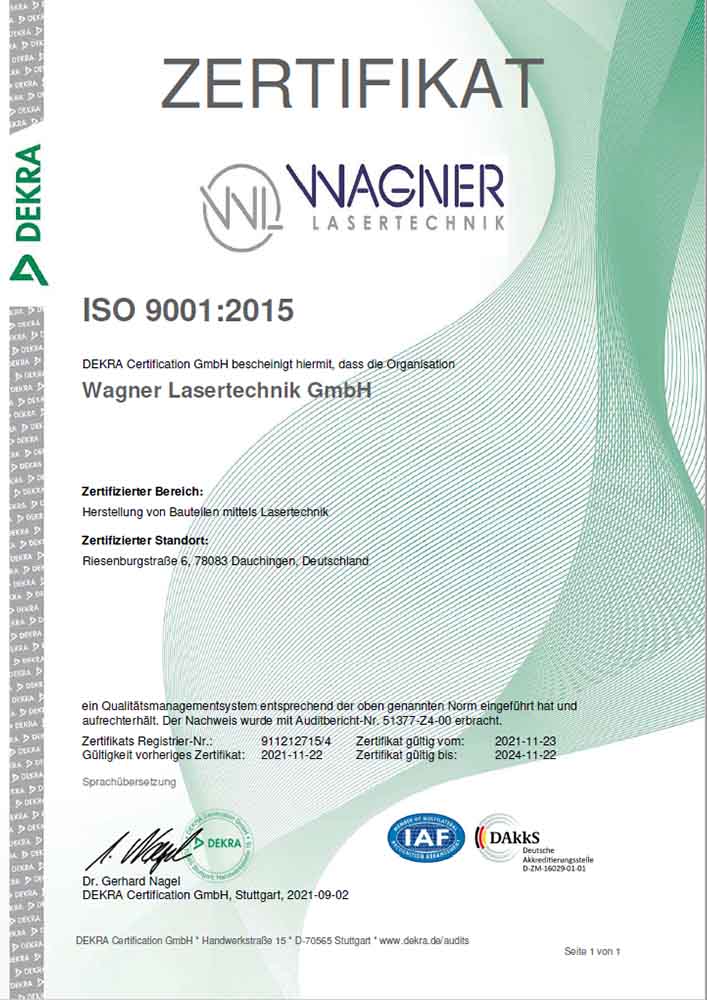

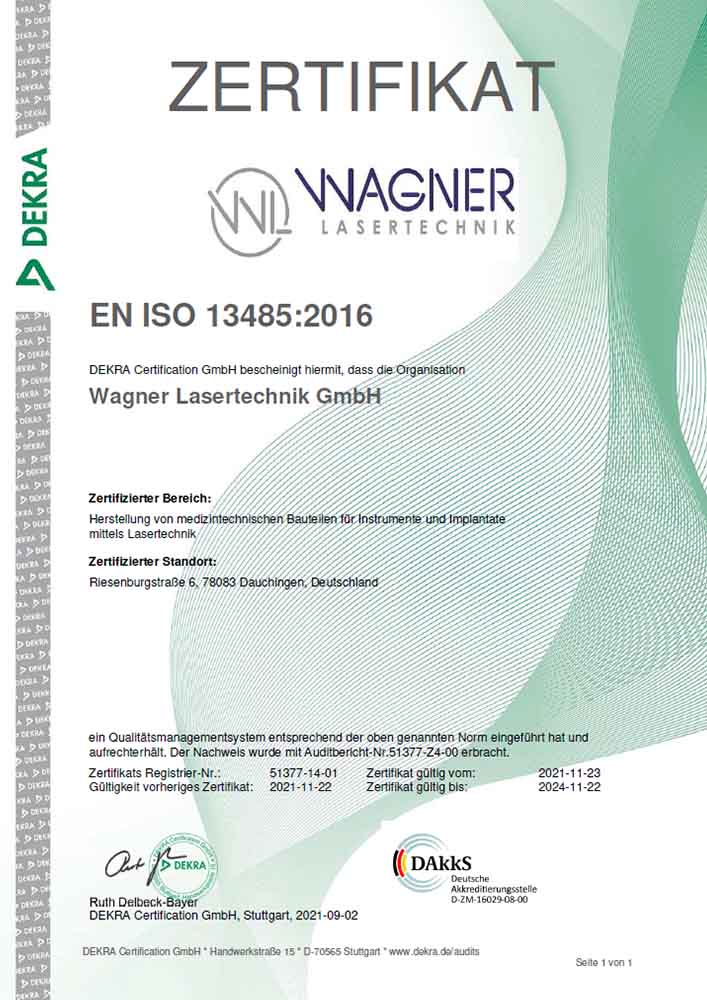

Our quality is inspected annually by DEKRA Certification GmbH and we hold EN ISO 13485 & DIN ISO 9001 certificates.

So you can be sure you have a professional on your side when you work together with Wagner Lasertechnik GmbH.

Automotive industry

Quelle: TRUMPF Group

We can quickly and precisely machine your formed parts/deep-drawn parts on our 3D laser cutting systems. Our know-how will take your project to the next level. As a reliable partner for prototypes and pilot production runs, we are available to assist you until the final tools are produced.

On request, we can undertake the following mechanical further processing stages on laser-cut components:

- grinding, mechanical/manual

- drilling

- countersinking

- isolating

- cleaning

Our quality is inspected annually by DEKRA Certification GmbH and we hold EN ISO 13485 & DIN ISO 9001 certificates.

So you can be sure you have a professional on your side when you work together with Wagner Lasertechnik GmbH.

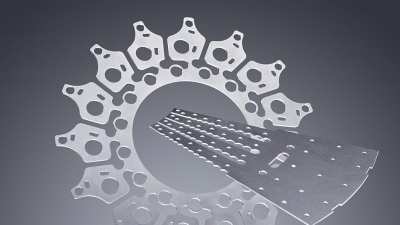

Precision engineering

Reference: TRUMPF Group

Laser cutting is perfect for producing sophisticated component geometries. The fine laser beam allows the smallest of ridge widths to be produced with ease on your component.

No matter whether you need high-precision gears or custom-fit springs, we can do this on our laser cutting systems.

We also provide a huge choice of different materials and material thicknesses to make your projects reality.

You can, of course, also provide your own material for your job.

On request, we can undertake the following mechanical further processing stages on laser-cut components:

- grinding, mechanical/manual

- drilling

- countersinking

- isolating

- cleaning

Our quality is inspected annually by DEKRA Certification GmbH and we hold EN ISO 13485 & DIN ISO 9001 certificates.

So you can be sure you have a professional on your side when you work together with Wagner Lasertechnik GmbH.

Electrical engineering

Reference: TRUMPF Group

You will find contact paths, current supplies and plugs in all electrical equipment.

We are happy to help you implement your projects. Our experience in metalworking, including that in machining alloys, makes us a strong partner.

Unlike with blanked parts, laser cutting doesn’t involve high tool costs.

We can provide a rapid and low-cost solution, even if you need to change things at short notice.

We also provide a huge choice of different materials and material thicknesses to make your projects reality.

You can, of course, also provide your own material for your job.

On request, we can undertake the following mechanical further processing stages on laser-cut components:

- grinding, mechanical/manual

- drilling

- countersinking

- isolating

- cleaning

Our quality is inspected annually by DEKRA Certification GmbH and we hold EN ISO 13485 & DIN ISO 9001 certificates.

So you can be sure you have a professional on your side when you work together with Wagner Lasertechnik GmbH.

Mechanical engineering

Reference: TRUMPF Group

Need precise components for your prototypes or small production runs and need them now?

We are happy to help you implement your projects. Our metalworking experience and our flexibility will drive your project.

We provide a huge choice of different materials and material thicknesses to make your projects reality.

You can, of course, also provide your own material for your job.

On request, we can undertake the following mechanical further processing stages on laser-cut components:

- grinding, mechanical/manual

- drilling

- countersinking

- isolating

- cleaning

Our quality is inspected annually by DEKRA Certification GmbH and we hold EN ISO 13485 & DIN ISO 9001 certificates.

So you can be sure you have a professional on your side when you work together with Wagner Lasertechnik GmbH.

Model making/jewellery

Your fantasy is the only limit when it comes to laser cutting. You can turn your designs into real gems.

Not only do we machine steel, titanium and stainless steels on our laser cutting systems, but also gold and silver. We can laser cut these materials up to a material thickness of 1 mm for you.

We provide a huge choice of different materials (other than gold, silver and platinum) and material thicknesses to make your projects reality.

You can, of course, also provide your own material for your job.

On request, we can undertake the following mechanical further processing stages on laser-cut components:

- grinding, mechanical/manual

- drilling

- countersinking

- isolating

- cleaning

Our quality is inspected annually by DEKRA Certification GmbH and we hold EN ISO 13485 & DIN ISO 9001 certificates.

So you can be sure you have a professional on your side when you work together with Wagner Lasertechnik GmbH.

Our services

Certification

Responsibility starts with a high quality standard. Wagner Lasertechnik GmbH operates a quality management system in line with DIN ISO 9001:2015 and DIN EN ISO 13485:2016 (medical technology). We set high standards in our processes and in the quality of our services.

Our certification gives you the peace of mind that you are working with a competent partner. Our work results are regularly inspected by independent assessors.

Wagner Lasertechnik

The company is run by the 2nd generation of the family

Our modern production facilities currently include:

Power levels of

100 W – 3000 W

Traverse paths up to

max. 800 mm x 600 mm

Plate shears up to max. 1000 mm

Huge variety and availability

Machine grinding for

high quality surface finish

Specialized in

perfect precision

All our laser cutting systems are equipped for 2D laser cutting. We have rotary axes on six CNC machining centres for machining cylindrical tubes. Two machining centres are equipped for 3D machining.

By using high-quality laser cutting systems, as well as delivering superlative repeat accuracy, we achieve a high level of precision and consistent quality in our laser-cut components.